How Digital Image Correlation (DIC) Reads the Whispers of Deformation

Ever wondered how engineers peer into the soul of materials? How they can measure the tiniest stretches and strains, the silent cries of a material under pressure?

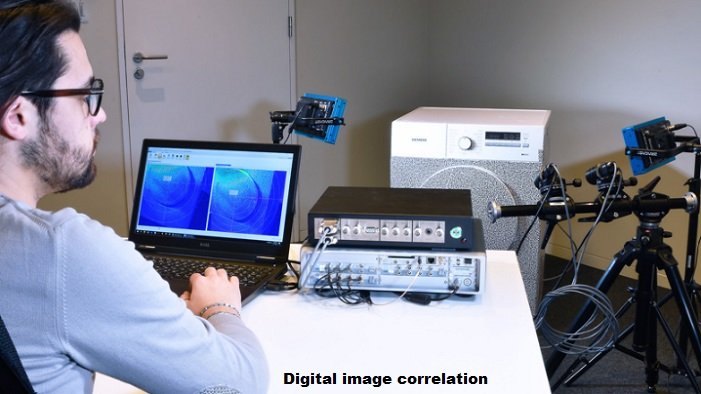

Well, one powerful tool in their arsenal is called Digital Image Correlation (DIC), and it’s like having a superpower for analyzing deformation.

Imagine you’re watching a video of a rubber band being pulled. You see the smooth surface deform, getting longer and thinner.

DIC takes this concept to a whole new level. By comparing high-resolution images of the object before and after deformation (like frames in a video), DIC can track the movement of every single speck on the surface.

But here’s the trick: the surface doesn’t have to have natural specks. Engineers can often paint a random pattern, almost like freckles, onto the material. These tiny specks become like ID tags, allowing DIC to follow their individual dance as the material deforms.

By analyzing how these specks move, DIC can calculate exactly how much the material has stretched, shrunk, or twisted in different areas.

This is like having a million tiny measuring tapes all working simultaneously, giving a complete picture of the deformation across the entire surface.

Why DIC is a Game Changer for Material Analysis

DIC offers a treasure trove of benefits compared to traditional methods like strain gauges or extensometers. Here’s why it’s a game changer:

- Full-Field Measurement: Unlike point-based methods, DIC captures deformation across the entire surface, not just at specific points. This gives a much richer understanding of how a material behaves under stress.

- Non-Contact Measurement: DIC doesn’t require attaching anything to the material, which can sometimes alter its behavior. This makes it ideal for delicate materials or situations where physical contact is undesirable.

- High-Resolution Analysis: DIC can measure incredibly small movements, down to a fraction of a pixel. This allows engineers to study the most subtle changes in a material’s response.

Read More:

Exploring the Battle: 10G vs 5G

DIC in Action: From Bridges to Biomaterials

DIC’s applications are vast and ever-expanding. Here are just a few examples:

- Testing the Strength of Bridges: Engineers use DIC to analyze how bridge components deform under load, helping to ensure their safety and longevity.

- Developing New Materials: Researchers use DIC to study the behavior of new materials under stress, accelerating the development of stronger, lighter, and more efficient materials.

- Understanding Bone Mechanics: Bioengineers use DIC to analyze the deformation of bones and implants, helping to design better prosthetics and understand the healing process.

DIC is a powerful tool that is revolutionizing the way we understand material behavior. By unveiling the whispers of deformation, DIC is helping us build safer structures, develop innovative materials, and even unlock the secrets of our own bodies.

This is just the beginning of the story of DIC. As technology and our understanding of materials science evolve, DIC will continue to play a vital role in pushing the boundaries of innovation.